Jacques Loom Documentation

About the ‘Jacques’ Project

The goal of this project is the development of a computerized Jacquard loom prototype called ‘Jacques’.

Jacquard weaving is a large-scale production method highly inaccessible for designers or non-professional users who need small quantities. Textiles or woven fabrics are mainly imported in large batches and entail a long and intransparent supply chain, including environmental and political issues such as violations of international human rights and, ultimately, disposal issues. There is hardly any possibility of a decentralized, local small-scale manufacturing of woven Jacquard fabrics.

To make Jacquard weaving more accessible and tackle the problems mentioned previously, I want to design an inexpensive and small Open Hardware open hardware Jacquard loom for private and small-scale usage. A new warp selection mechanism will make the loom significantly cheaper and smaller to build than the current industry standards but compromises speed and tissue density as a trade-off.

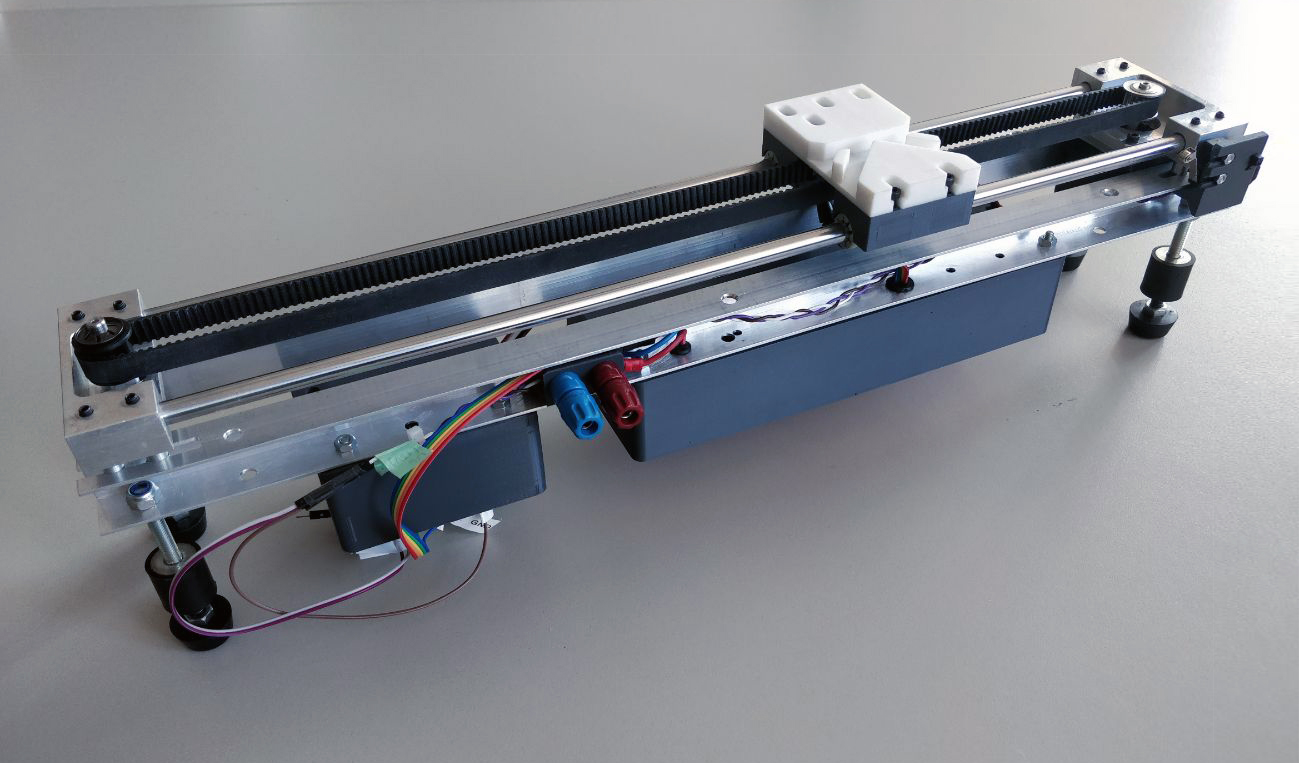

The test rig for experimenting with different warp selection mechanisms

The test rig for experimenting with different warp selection mechanisms

The project will be an open hardware project- comprehensible for other people to rebuild and improve with a transparent development phase through a build log on this website. I try to explain and illuminate my (design) decisions in this particular regard. The CAD files, Gerber files and schematics, bill of materials, software code and detailed assembly instructions will be available to the public. The ultimate goal is a fully functional machine that goes beyond a proof of concept status and serves as a real production tool.

The interim report and the first prototypes will be the practical project of my master’s degree at the University of Applied Sciences Hamburg.

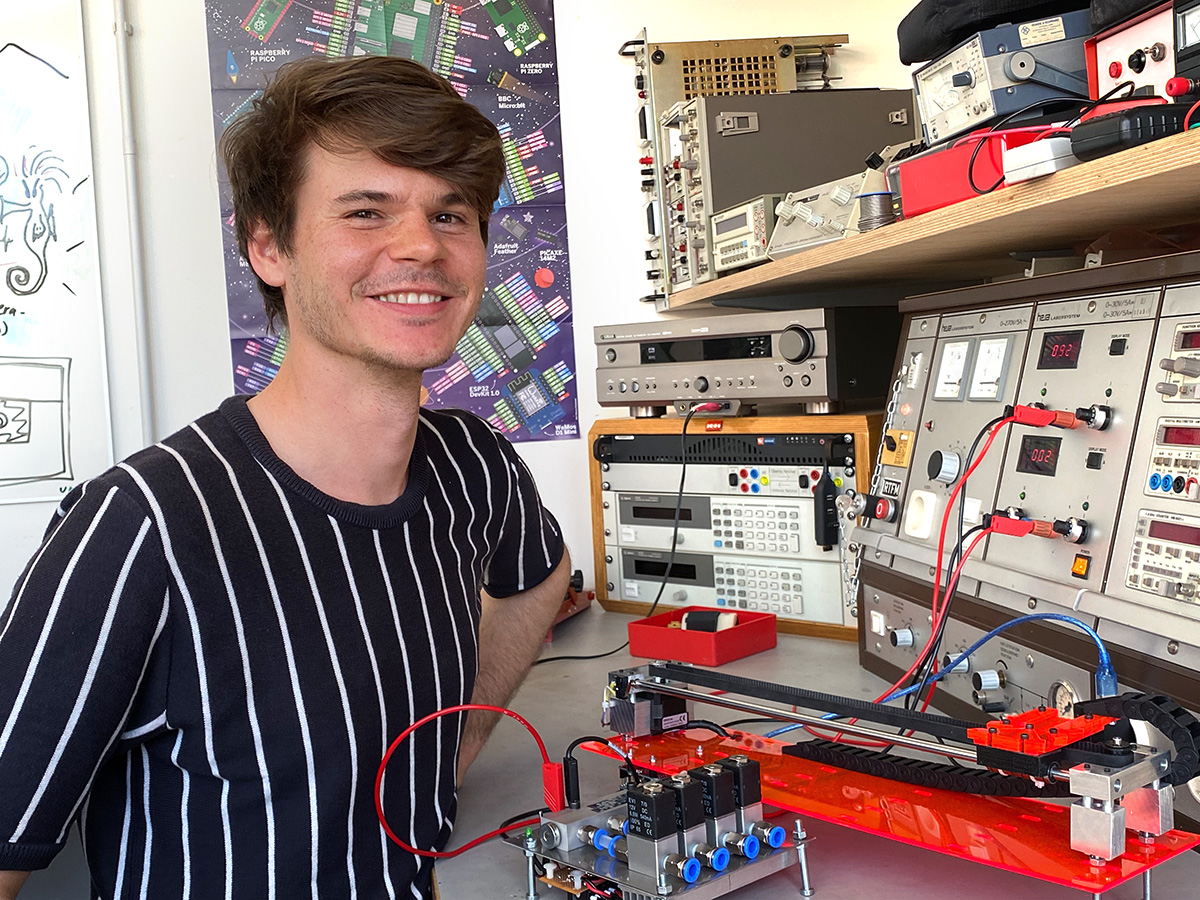

About me

Hi! 👋 My name is Norman, and I’m an industrial designer and maker. I am a master’s student at the University of Applied Sciences (Department Design). Prior to the development of this loom, I worked at the german electron synchrotron (DESY) on a project for early childhood STEM education, as well as the work on various websites and user interfaces, a large format 3D printer with a tool changer, the multimedia installation ‘Confessional3000’ and furniture systems for highly flexible working environments (SCOPE & FRAMEWORKER).

Acknowledgements

Special thanks to Dr Bettina Schmidt for all the support and care; Bettina, Maya and Sabine for proofreading; Dominic and Eric for technical and electrical advice; Sabine for taking photos and videos and making the promo video, Attraktor e.V. for providing the tools and infrastructure to bootstrap such a project, especially Flo for the laser cutter introduction course and Frank for the initiation; Prof. Dr Kabel and Prof. Aram Bartholl for supervision. Thanks to Mom and Dad.